New developments in test equipment

Bosch diagnostic system – case study

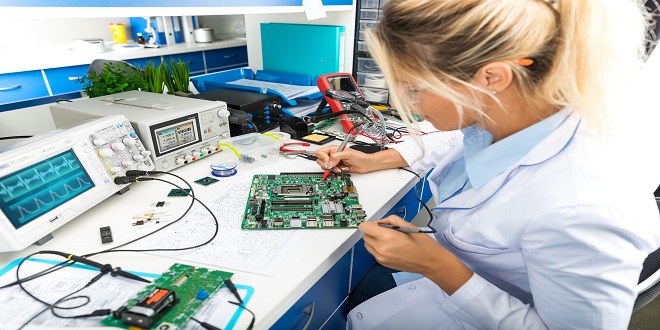

Modern vehicles are being fitted with more and more electronics. This complicates diagnosis and repair, especially as the individual systems are often interlinked. The work of service and repair workshops is being fundamentally changed. Automotive engineers have to continually update their knowledge of vehicle electronics.

But this is no longer sufficient on its own. The ever-growing number of electrical and electronic vehicle components is no longer manageable without modern diagnostic technology – such as the latest range of KTS control unit diagnostic testers from Bosch.

Used in conjunction with the comprehensive Esitronic workshop software, the testers offer the best possible basis for the efficient diagnosis and repair of electrical and electronic components in modern vehicles. The testers are available in different versions, suited to the individual requirements of the particular workshop

- The portable KTS 650 with built-in computer and touch-screen can be used anywhere. It has a 20 GB hard drive, a touch-screen and a DVD drive. When being used away from the workshop, the power supply of the KTS 650 comes from the vehicle battery or from rechargeable batteries with one to two hours’ service life. For use in the workshop there is a tough wheeled trolley with a built-in charger unit. As well as having all the necessary adapter cables the trolley can also carry an inkjet printer and an external keyboard, which can be connected to the KTS 650 via the usual PC interfaces

- The KTS 520 is designed as a module for operation in conjunction with a laptop or for upgrading a stationary PC-supported tester, such as Bosch’s ESA Emissions System Analysis or similar equipment from other manufacturers possessing a standard interface. The workshop software is stored on the hard disk of the workshop tester

- The KTS 550 is also intended as an upgrade module or for use with a laptop. In addition, and in common with the KTS 650 it has a twin-channel oscilloscope and a twin-channel multimeter.

- Common Rail diesel systems, for example, even special functions such as quantitative comparison and compression testing can be carried out. This allows for reliable diagnosis of the faulty part and avoids unnecessary dismantling and re-assembly, or the removal and replacement of non-faulty parts.

Modern diagnostic equipment is also indispensable when workshops have to deal with braking systems with electronic control systems such as ABS, ASR and ESP. Nowadays the diagnostic tester is even needed for bleeding a brake system of air

In addition, KTS and Esitronic allow independent workshops to reset the service interval warning, for example after an oil change or a routine service, or perhaps find the correct default position for the headlamps after one or both of these have been replaced.

The three KTS versions are equipped for all current diagnostic protocols. As well as ISO norms for European vehicles and SAE norms for American and Japanese vehicles, the KTS testers can also deal with CAN norms for checking modern CAN bus systems, which are coming into use more and more frequently in new vehicles. The testers are connected directly to the diagnostics socket via a serial diagnostics interface by means of an adapter cable.

Last word

The system automatically detects the control unit and reads out the actual values, the error memory and other controller-specific data. Thanks to the built-in multiplexer, it is even easier for the user to diagnose the various systems in the vehicle. The multiplexer determines the connection in the diagnostics socket so that communication is established correctly with the selected control unit.